Krater - Mixing Water with Wine - Wide mouth

Hydra - Carrying water - narrow mouth with lid

Kylix - Drinking cup - 2 handled flat

Oinochoe - Wine Jug - tall jug, narrow mouth usually with pouring spout

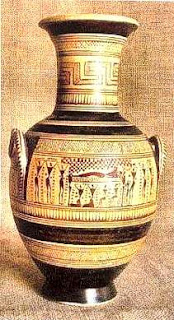

Amphora - Storage for supplies - Large, tall urn

tall, two-handled storage vessel for wine, corn, oil, or honey;

Khyton - Wine drinking usually a character

Friday, December 28, 2007

Pottery - major art in classical Greece

The fashioning and painting of ceramics was a major art in classical Greece. Native clay was shaped easily on the wheel, and each distinct form had a name and a specific function in Greek society and ceremonial: The amphora was a tall, two-handled storage vessel for wine, corn, oil, or honey; the hydria, a three-handled water jug; the lecythus, an oil flask with a long, narrow neck, for funeral offerings; the kylix, a double-handled drinking cup on a foot; the oenochoe, a wine jug with a pinched lip; the krater, a large bowl for mixing wine and water. Undecorated black pottery was used throughout Greek and Hellenistic times, the forms being related either to those of decorated pottery or those of metalwork. Both styles influenced Roman ceramics.

Even in the Bronze Age, the Greeks took advantage of oxidizing and reducing kilns to produce a shiny black slip on a cream, brownish, or orange-buff body, the shade depending on the type of clay. At first, decorative designs were abstract. By the Middle Bronze Age (2000-1500 BC), however, stylized forms from nature appeared. By the Late Bronze Age, plants, sea creatures, and fanciful animals were painted on pots of well-conceived shape by the Mycenaeans, who were initially influenced by Cretan potters. Athenian geometric style replaced the Mycenaean about 1000 BC and declined by the 6th century BC. Large kraters in the Geometric style, with bands of ornament, warriors, and processional figures laid out in horizontal registers, were found at the Dipylon cemetery of Athens; they date from about 750 BC.

Even in the Bronze Age, the Greeks took advantage of oxidizing and reducing kilns to produce a shiny black slip on a cream, brownish, or orange-buff body, the shade depending on the type of clay. At first, decorative designs were abstract. By the Middle Bronze Age (2000-1500 BC), however, stylized forms from nature appeared. By the Late Bronze Age, plants, sea creatures, and fanciful animals were painted on pots of well-conceived shape by the Mycenaeans, who were initially influenced by Cretan potters. Athenian geometric style replaced the Mycenaean about 1000 BC and declined by the 6th century BC. Large kraters in the Geometric style, with bands of ornament, warriors, and processional figures laid out in horizontal registers, were found at the Dipylon cemetery of Athens; they date from about 750 BC.

Attic potters introduced black-figure ware in the early 6th century. Painted black forms adorned the polished red clay ground, with detail rendered by incising through the black. White and reddish-purple were added for skin and garments. Depictions of processions and chariots continued; animals and hybrid beasts (particularly in the Orientalizing phase that followed the Geometric period) were also shown, at times surrounded by geometric or vegetal motifs. Such decoration was always well integrated with the vessel shapes, and the iconography of Greek mythology can be identified. Beginning in the 6th century, the decoration stressed humans far more than animals. Favorite themes included people and gods at work, battle, and banquet; musicians; weddings and other ceremonies; and women at play or dressing. In some cases, events or heroes were labeled. Mythological and literary scenes became more frequent. Potters' and painters' names and styles have been identified, even when they did not sign their works.

Red-figure pottery was invented about 530 BC, becoming especially popular between 510 and 430. The background was painted black, and the figures were left in reserve on the red-brown clay surface; details on the figures were painted in black, which allowed the artist greater freedom in drawing. The paint could also be diluted for modulating the color. Secondary colors of red and white were less used; gold was sometimes added for details of metal and jewelry. Anatomy was rendered more realistically, and after 480, so were nuances of gesture and expression. Although Athens and Corinth were centers for red-figure pottery, the style also spread to the Greek islands. By the 4th century BC, however, it declined in quality. Another Greek style featured outline drawing on a white ground, with added colors imitating monumental painting; these vessels, however, were impractical for domestic use.

Source

Even in the Bronze Age, the Greeks took advantage of oxidizing and reducing kilns to produce a shiny black slip on a cream, brownish, or orange-buff body, the shade depending on the type of clay. At first, decorative designs were abstract. By the Middle Bronze Age (2000-1500 BC), however, stylized forms from nature appeared. By the Late Bronze Age, plants, sea creatures, and fanciful animals were painted on pots of well-conceived shape by the Mycenaeans, who were initially influenced by Cretan potters. Athenian geometric style replaced the Mycenaean about 1000 BC and declined by the 6th century BC. Large kraters in the Geometric style, with bands of ornament, warriors, and processional figures laid out in horizontal registers, were found at the Dipylon cemetery of Athens; they date from about 750 BC.

Even in the Bronze Age, the Greeks took advantage of oxidizing and reducing kilns to produce a shiny black slip on a cream, brownish, or orange-buff body, the shade depending on the type of clay. At first, decorative designs were abstract. By the Middle Bronze Age (2000-1500 BC), however, stylized forms from nature appeared. By the Late Bronze Age, plants, sea creatures, and fanciful animals were painted on pots of well-conceived shape by the Mycenaeans, who were initially influenced by Cretan potters. Athenian geometric style replaced the Mycenaean about 1000 BC and declined by the 6th century BC. Large kraters in the Geometric style, with bands of ornament, warriors, and processional figures laid out in horizontal registers, were found at the Dipylon cemetery of Athens; they date from about 750 BC.Attic potters introduced black-figure ware in the early 6th century. Painted black forms adorned the polished red clay ground, with detail rendered by incising through the black. White and reddish-purple were added for skin and garments. Depictions of processions and chariots continued; animals and hybrid beasts (particularly in the Orientalizing phase that followed the Geometric period) were also shown, at times surrounded by geometric or vegetal motifs. Such decoration was always well integrated with the vessel shapes, and the iconography of Greek mythology can be identified. Beginning in the 6th century, the decoration stressed humans far more than animals. Favorite themes included people and gods at work, battle, and banquet; musicians; weddings and other ceremonies; and women at play or dressing. In some cases, events or heroes were labeled. Mythological and literary scenes became more frequent. Potters' and painters' names and styles have been identified, even when they did not sign their works.

Red-figure pottery was invented about 530 BC, becoming especially popular between 510 and 430. The background was painted black, and the figures were left in reserve on the red-brown clay surface; details on the figures were painted in black, which allowed the artist greater freedom in drawing. The paint could also be diluted for modulating the color. Secondary colors of red and white were less used; gold was sometimes added for details of metal and jewelry. Anatomy was rendered more realistically, and after 480, so were nuances of gesture and expression. Although Athens and Corinth were centers for red-figure pottery, the style also spread to the Greek islands. By the 4th century BC, however, it declined in quality. Another Greek style featured outline drawing on a white ground, with added colors imitating monumental painting; these vessels, however, were impractical for domestic use.

Source

Sunday, December 23, 2007

Frankoma Pottery

It wasn't so long ago that many pieces of Frankoma pottery languished on antique shop shelves collecting dust. Although Frankoma did have a few admirers, the company's older items produced during the 1930s were the main focus for pottery lovers for many years. Now the more common Frankoma pieces are getting more attention, and prices are starting to rise accordingly. Finally, it's fashionable to take another look at Frankoma pottery.

Frankoma's Origin

The founder of the company, John Frank, came to Oklahoma in 1927 as an art and pottery teacher at the University of Oklahoma. Working on various geological digs, he discovered the rich clays of the region and set up a studio using a butter churn to mix the clay and a fruit jar to grind the glazes. It wasn't long till he left his teaching position to further his love for creating pottery, according to the company's Web site.

Frankoma pieces made since 1954 sport a red clay from Sapulpa, Okla.

in comparison to the older pieces formed with a tan colored clay dug at Ada, Okla. Using these source names of Sapulpa and Ada, along with glaze colors and item styles, collectors are able to identify and date Frankoma Pottery.

Frankoma's Inspiration and Colors

The Great Southwest served as inspiration for many Frankoma works. The factory formed pitchers shaped like wagon wheels, attractive boot-shaped vases and interesting Native American masks over the years. Even their dinnerware patterns have a western flair.

Two of their most recognizable glazes are named Prairie Green and Desert Gold. In fact, many people associate Frankoma entirely with their medium green glaze that seemed rather dated and unattractive until recently. Since both these colors were used extensively over the years, it's the type of clay used in the piece rather than the color of the glaze, which determines value in this instance.

Many of their works, such as their dated political mugs shaped like elephants and donkeys, feature a wide variety of colors. Other series pieces, including bicentennial plates, were also very colorful. And most of these pieces are still relatively affordable, even for the beginning collector.

Pricing Frankoma

The colorful political mugs range in price from about $10-60 and bicentennial plates generally sell in the $15 range with a couple of exceptions for rarities. A 1974 Nixon/Ford elephant mug can sell for several hundred dollars because so few were produced. And a 1972 plate, with the word "states" spelled as "statis" because of a mold flaw, usually sells for more than $100. Many of the Wagon Wheel dinnerware pieces still sell for less than $20 apiece, with only the serving pieces pressing into the $30-75 range.

With the older Frankoma pieces being hard to find and priced quite high, listing in the $1,000-$5,000 range per piece when sold by a knowledgeable dealer, the more recent Frankoma works have garnered some interest during the past couple of years. The dusty treasures once ignored by pottery shoppers have taken on a new light as collectors make a place for them in their homes.

Source

Frankoma's Origin

The founder of the company, John Frank, came to Oklahoma in 1927 as an art and pottery teacher at the University of Oklahoma. Working on various geological digs, he discovered the rich clays of the region and set up a studio using a butter churn to mix the clay and a fruit jar to grind the glazes. It wasn't long till he left his teaching position to further his love for creating pottery, according to the company's Web site.

Frankoma pieces made since 1954 sport a red clay from Sapulpa, Okla.

in comparison to the older pieces formed with a tan colored clay dug at Ada, Okla. Using these source names of Sapulpa and Ada, along with glaze colors and item styles, collectors are able to identify and date Frankoma Pottery.

Frankoma's Inspiration and Colors

The Great Southwest served as inspiration for many Frankoma works. The factory formed pitchers shaped like wagon wheels, attractive boot-shaped vases and interesting Native American masks over the years. Even their dinnerware patterns have a western flair.

Two of their most recognizable glazes are named Prairie Green and Desert Gold. In fact, many people associate Frankoma entirely with their medium green glaze that seemed rather dated and unattractive until recently. Since both these colors were used extensively over the years, it's the type of clay used in the piece rather than the color of the glaze, which determines value in this instance.

Many of their works, such as their dated political mugs shaped like elephants and donkeys, feature a wide variety of colors. Other series pieces, including bicentennial plates, were also very colorful. And most of these pieces are still relatively affordable, even for the beginning collector.

Pricing Frankoma

The colorful political mugs range in price from about $10-60 and bicentennial plates generally sell in the $15 range with a couple of exceptions for rarities. A 1974 Nixon/Ford elephant mug can sell for several hundred dollars because so few were produced. And a 1972 plate, with the word "states" spelled as "statis" because of a mold flaw, usually sells for more than $100. Many of the Wagon Wheel dinnerware pieces still sell for less than $20 apiece, with only the serving pieces pressing into the $30-75 range.

With the older Frankoma pieces being hard to find and priced quite high, listing in the $1,000-$5,000 range per piece when sold by a knowledgeable dealer, the more recent Frankoma works have garnered some interest during the past couple of years. The dusty treasures once ignored by pottery shoppers have taken on a new light as collectors make a place for them in their homes.

Source

Monday, December 10, 2007

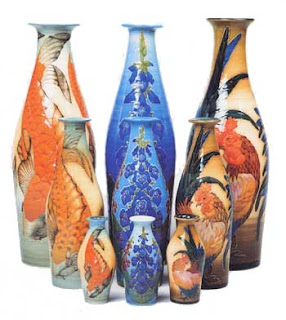

The Dennis Chinaworks pottery - stylish, fun, beautiful!

Founded in 1993 by Sally and Richard Dennis, the Dennis Chinaworks pottery is run from the converted stables of a Victorian Gothic rectory in Somerset, England.

Sally established her professional name in design (she works as Sally Tuffin). Foale & Tuffin soon became one of the leading design houses of the 1960’s. Sally later took her skills and experience into ceramics, becoming partner and design director of the Moorcroft Pottery from 1986 to 1993.

Richard trained with the auctioneers Sotheby’s before establishing an antique glass and ceramic business together with a publishing house producing specialist books for collectors.

The pots are thrown and turned on the wheel. Colour is spun on the leather hard earthenware and decorated by incising and slip-trailing the designs. Further colour is added using underglazes and natural oxides, then the pots are finished with a clear glaze.

From beginning to end each pot is the work of a single Decorator. Their signature joins the number, company name, date and throwers mark on the base.

The pottery’s products, vases, bowls, boxes and dishes are bought by collectors and enthusiasts of decorative pottery. Although influenced by many sources, the designs are distinctly Sally Tuffin, reflecting her love of the late 19th - early 20th century Arts & Crafts movement.

Source

Sunday, October 21, 2007

...and Fun Pigs

This adorable piggy will make your little one smile every time she or he sees it.

Source

Individually hand-thrown and modeled in Iowa, this functional pottery bank is a sculptural delight. Ideally suited for kids and adults alike, each irresistible Big Pig features large floppy ears, a 1.25" slot for coins and a removable cork stopper.

Source

Monday, October 15, 2007

The Beauty of Mexican Pottery

All pottery from around the world has some similar qualities to all other pottery and some qualities that are unique to the culture in which it was crafted and created. There is much that goes into the creation of pottery pieces from the clay that is molded and shaped to the intricacy of carvings, paintings, glazing, and even the firing method that is used to, in essence, create the actual pottery piece. This is often considered to be among the most beautiful forms of pottery in the world today. Of course there are those who disagree as beauty is in the eye of the beholder but there is little doubt that it is among some of the most intricately designed pottery you will find around the world today.

The Mexican pottery of today is made combining ancient methods with modern technology for a grand and beautiful effect. Some of the more elegant pieces of this pottery on the market today are hand built rather than crafted on a potter's wheel and very few are made with the use of ceramics, relying instead on clay for these beautiful pieces of pottery. Various potters will have different styles of crafting their creations. Some may use the wheel while others will not. Keep in mind that many of the finer pieces that are most often associated with the best of Mexican pottery offerings are those that are made as mentioned above.

This is sold around the world and greatly coveted by those who have a sincere interest in collecting pottery for its beauty and the method of design, which combines some of the ancient traditions that have been passed down through generations among artisans with the best in new technologies with a stunning appeal.

Not all Mexican pottery is serious business however; there are plenty of pieces that are perfect for those looking to collect the more unusual, off the wall, and whimsical pieces of potter that can be found if one knows where to look. Mexican pottery sometimes takes on the shape of whatever the artist happens to fancy at the moment, depending of course on how seriously the artist takes him or herself. If you are in the mood to collect some of the mythical creatures of Mexican folklore, chances are that you can find a potter that will incorporate these beasts into his or her work (for the right price of course). There have been some quite famous pieces that have been completely whimsical in nature and serve as a great reminder that we really should avoiding taking our lives and ourselves so seriously all the time. Life is best enjoyed when the living are smiling and having fun.

The Mexican pottery of today is made combining ancient methods with modern technology for a grand and beautiful effect. Some of the more elegant pieces of this pottery on the market today are hand built rather than crafted on a potter's wheel and very few are made with the use of ceramics, relying instead on clay for these beautiful pieces of pottery. Various potters will have different styles of crafting their creations. Some may use the wheel while others will not. Keep in mind that many of the finer pieces that are most often associated with the best of Mexican pottery offerings are those that are made as mentioned above.

This is sold around the world and greatly coveted by those who have a sincere interest in collecting pottery for its beauty and the method of design, which combines some of the ancient traditions that have been passed down through generations among artisans with the best in new technologies with a stunning appeal.

Not all Mexican pottery is serious business however; there are plenty of pieces that are perfect for those looking to collect the more unusual, off the wall, and whimsical pieces of potter that can be found if one knows where to look. Mexican pottery sometimes takes on the shape of whatever the artist happens to fancy at the moment, depending of course on how seriously the artist takes him or herself. If you are in the mood to collect some of the mythical creatures of Mexican folklore, chances are that you can find a potter that will incorporate these beasts into his or her work (for the right price of course). There have been some quite famous pieces that have been completely whimsical in nature and serve as a great reminder that we really should avoiding taking our lives and ourselves so seriously all the time. Life is best enjoyed when the living are smiling and having fun.

Sunday, October 14, 2007

How was the imperial Chinese ceramics made

The production of porcelain was a detailed affair and mass production techniques made use of the specialized labor of many different artisans. No one person handled the process from beginning to end, rather every worker had one job only and several workshops handled different aspects of the production. One worker would form a bowl, while another would mold it. Another would chisel it and yet another would apply the underglaze, and so on down the line until a piece was finished. Dozens of people could be involved in the making of one bowl. Using cobalt, which had not been available to earlier generations of artisans, as it was an import, craftsmen applied beautiful designs to unfired pieces and the result was the famous blue and white Ming porcelain. During the sixteenth century, the vast amount of orders for porcelain came from the imperial palace. As well as being used in the palace, many pieces were commissioned as gifts. Quality control of imperial porcelain was rigorous. Every piece destined for imperial use had special markings, but the tiniest imperfection would cause a piece to be broken into pieces and discarded, as imperial porcelain could not be used for any other purpose.

Yuan Dynasty

Yuan Dynasty

Blue and white porcelain was first produced under the Yuan dynasty (1279-1368 AD). Baked at an extremely high temperature, porcelain is characterized by the purity of its kaolin clay body.

Ming Dynasty

Ming Dynasty

Potters of the subsequent Ming dynasty (1368-1644) perfected these blue and white wares so that they soon came to represent the virtuosity of the Chinese potter. Jingedezhen, in Jiangxi province, became the center of a porcelain industry that not only produced vast quantities of imperial wares, but also exported products as far afield as Turkey. While styles of decorative motif and vessel shape changed with the ascension to the throne of each new Ming emperor, the quality of Ming blue and whites are indisputably superior to that of any other time period.

Qing Dynasty

Qing Dynasty

During the Qing dynasty (1644-1911), porcelain was enriched with the innovation of five-coloured wares. Applying a variety of under-glaze pigments to decorative schemes of flower, landscape and figurative scenes, these wares have gained greatest renown in the West. In almost every major European museum, you will find either a five-colored ware or a monochromatic ware (in blue, red, yellow or pink) from this period.

The quality of Chinese porcelain began to decline from the end of the Qing dynasty as political instability took its inevitable toll on the arts. However, the production of porcelain is being revived as Chinese culture gains greater recognition both at home and abroad. In addition to modern interpretations, numerous kiln centers have been established to reproduce the more traditional styles.

For over six centuries, blue and white Ming Dynasty porcelain has been a favorite of collectors around the world. Blue and white porcelain was immensely popular and formed the mainstream of Ming ceramics. As ceramic kilns flourished, the material quality of the porcelain wares achieved a high level of excellence. Jingdezhen in Jiangxi province became the focal print of porcelain manufacture throughout the country. We may note that the Dehua kilns located in southern Fujian province also produced a high amount of white porcelain.

Some fine white porcelain was made at Dehua in the province of Fujian in South China from the 1400s to the 1700s. Some of this ware was brought to Europe by early traders, where it was known as blanc de chine. It provided many models for the early European porcelain makers.

Yuan Dynasty

Yuan DynastyBlue and white porcelain was first produced under the Yuan dynasty (1279-1368 AD). Baked at an extremely high temperature, porcelain is characterized by the purity of its kaolin clay body.

Ming Dynasty

Ming DynastyPotters of the subsequent Ming dynasty (1368-1644) perfected these blue and white wares so that they soon came to represent the virtuosity of the Chinese potter. Jingedezhen, in Jiangxi province, became the center of a porcelain industry that not only produced vast quantities of imperial wares, but also exported products as far afield as Turkey. While styles of decorative motif and vessel shape changed with the ascension to the throne of each new Ming emperor, the quality of Ming blue and whites are indisputably superior to that of any other time period.

Qing Dynasty

Qing DynastyDuring the Qing dynasty (1644-1911), porcelain was enriched with the innovation of five-coloured wares. Applying a variety of under-glaze pigments to decorative schemes of flower, landscape and figurative scenes, these wares have gained greatest renown in the West. In almost every major European museum, you will find either a five-colored ware or a monochromatic ware (in blue, red, yellow or pink) from this period.

The quality of Chinese porcelain began to decline from the end of the Qing dynasty as political instability took its inevitable toll on the arts. However, the production of porcelain is being revived as Chinese culture gains greater recognition both at home and abroad. In addition to modern interpretations, numerous kiln centers have been established to reproduce the more traditional styles.

For over six centuries, blue and white Ming Dynasty porcelain has been a favorite of collectors around the world. Blue and white porcelain was immensely popular and formed the mainstream of Ming ceramics. As ceramic kilns flourished, the material quality of the porcelain wares achieved a high level of excellence. Jingdezhen in Jiangxi province became the focal print of porcelain manufacture throughout the country. We may note that the Dehua kilns located in southern Fujian province also produced a high amount of white porcelain.

Some fine white porcelain was made at Dehua in the province of Fujian in South China from the 1400s to the 1700s. Some of this ware was brought to Europe by early traders, where it was known as blanc de chine. It provided many models for the early European porcelain makers.

Gzhel Porcelain and pottery from Russia

Gzhel is the name of a major ceramics center situated some fifty kilometers southeast of Moscow. The village of Gzhel is mentioned for the first time in the fourteenth century in the testament of Ivan Kalita the Moneybag, the Grand Prince of Muscovy. Otherwise historical chronicles note that the dominant pursuit of the local population was the making of pottery, for which reason the very name of Gzhel derives in all likelihood from the Russian verb zhech which means burn in the sense of firing clay. Though the secrets of the craft were handed down from generation to generation long before, Gzhel really rose to fame as a large center of ceramics in the eighteenth century when local potters mastered the making of majolica or majolica tin-glazed earthenware, which owes sonbriguet to the island of Majorca, where these ceramic wares were made.

At that time majolica wares were called in Russia tsenina. The origin of the word is not known exactly. Majolica wares were termed in Europe faience. The product was usually made of tinted clays, had a massive porous shell, and was decorated with enamel colours in polychromatic, typically peasant-style designs. True, tsenina was first manufactured in Moscow at the establishment of the merchant Afanasy Grebenshchikov, who employed a number of potters from Gzhel. Returning home and having learned the secrets of majolica manufacture, they started their own potteries. Though we have no idea who they were-their names have been lost - they made so fine a start that within the space of but several years, Gzhel majolica was already successfully competing with Grebenshchikov's produce.

Whereas the celebrated Italian Renaissance majolica borrowed subject material from contemporary painting and served an exclusively decorative purpose (produced mostly were large vases, giant dishes and bas-reliefs), Gzhel ware was, on the contrary, of utilitarian shape and form and was decorated with the two-dimensional designs that are typically of folk origin; the large local pools of bright color displayed a marked affinity with the lubok, the Russian folk picture or broadside.

The range of Gzhel majolica included virtually the entire assortment of domestic utensils, such as breakfast and soup plates, dinner-services, mugs, tankards, and pitchers. More often that was only white-glazed earthenware devoid of decoration; however it was prized precisely because of its hygienic whiteness.

Saturday, October 13, 2007

The history of imperial Chinese pottery

It began some eight thousand years ago with the crafting of hand-molded earthenware vessels. Soon after, in the late neolithic period, the potter's wheel was invented facilitating the production of more uniform vessels. The sophistication of these early Chinese potters is best exemplified by the legion of terracotta warriors found in the tomb of Emperor Qin (r. 221-206 BC).

In China the potter's workmanship was lifted above the utilitarian level and became a fine art. The great work of the imperial potters at the peak of their excellence has never been equaled in modern times.

Pottery was made in China long before history was set down in writing. It is from the Han Dynasty (202 BC-AD 220) that the history of pottery making in China is ordinarily traced. The ancient Chinese had a custom of burying the dead with pottery images of people, animals, and possessions dear to them during life. These images have given modern students a clear insight into the life and customs of these people. The period of disunity (220-581) is noted for vigorous modeling of figures, particularly of animals. A coarse gray earthenware was made before the Shang Dynasty (1766-1122 BC), and a finer white pottery was made during this era. These vessels resemble in size and shape the Chinese bronze vessels of the same period, and it is likely that the bronzes were first copied from pottery.

Tang Dynasty

Tang Dynasty

Over the following centuries innumerable new ceramic technologies and styles were developed. One of the most famous is the three-colored ware of the Tang dynasty (618-907 AD), named after the bright yellow, green and white glazes which were applied to the earthenware body. They were made not only in such traditional forms as bowls and vases, but also in the more exotic guises of camels and Central Asian travelers, testifying to the cultural influence of the Silk Road. Another type of ware to gain the favor of the Tang court were the qingci, known in the West as celadons. These have a subtle bluish-green glaze and are characterized by their simple and elegant shapes. They were so popular that production continued at various kiln centers throughout China well into the succeeding dynasties, and were shipped as far as Egypt, Southeast Asia, Korea and Japan.

In China the potter's workmanship was lifted above the utilitarian level and became a fine art. The great work of the imperial potters at the peak of their excellence has never been equaled in modern times.

Pottery was made in China long before history was set down in writing. It is from the Han Dynasty (202 BC-AD 220) that the history of pottery making in China is ordinarily traced. The ancient Chinese had a custom of burying the dead with pottery images of people, animals, and possessions dear to them during life. These images have given modern students a clear insight into the life and customs of these people. The period of disunity (220-581) is noted for vigorous modeling of figures, particularly of animals. A coarse gray earthenware was made before the Shang Dynasty (1766-1122 BC), and a finer white pottery was made during this era. These vessels resemble in size and shape the Chinese bronze vessels of the same period, and it is likely that the bronzes were first copied from pottery.

Tang Dynasty

Tang DynastyOver the following centuries innumerable new ceramic technologies and styles were developed. One of the most famous is the three-colored ware of the Tang dynasty (618-907 AD), named after the bright yellow, green and white glazes which were applied to the earthenware body. They were made not only in such traditional forms as bowls and vases, but also in the more exotic guises of camels and Central Asian travelers, testifying to the cultural influence of the Silk Road. Another type of ware to gain the favor of the Tang court were the qingci, known in the West as celadons. These have a subtle bluish-green glaze and are characterized by their simple and elegant shapes. They were so popular that production continued at various kiln centers throughout China well into the succeeding dynasties, and were shipped as far as Egypt, Southeast Asia, Korea and Japan.

Milestones in the history of mankind

Pottery is a type of ceramic material, which the American Society for Testing and Materials (ASTM) has defined as "(a)ll fired ceramic wares that contain clay when formed, except technical, structural, and refractory products." The term pottery is also used for a technique involving ceramic, where clay is mixed with other minerals and is formed into objects, including vessels generally designed for utilitarian purposes.

A Pottery is a facility of any size, from a modest studio to an industrialized factory, where pottery is made. Where resources are available - raw materials, workers, transportation - groups of potteries may exist. Due to the large number of pottery factories, or colloquially 'Pot Banks', the City of Stoke-on-Trent in England became known as The Potteries; one of the first industrial cities of the modern era where as early as 1785 200 pottery manufacturers employed 20,000 workers. The Potters is the nickname of the local football club, Stoke City F.C.. The same name is used for sports teams in the one-time "Pottery Capital of the World," East Liverpool, Ohio.

Pottery production is a process where wet clay body, clay mixed with other minerals, is shaped and allowed to dry. The shaped clay body, or piece, ware or article, may be "bisque or biscuit fired" in a kiln to induce permanent changes that result in increased mechanical strength, and then fired a second time after adding a glaze or a piece may be once fired by applying appropriate glaze to the dry unfired clay and firing in one cycle.

Types of pottery

Aesthetic and artistic considerations have often been part of the formation of the pottery vessels, however modern mass production techniques have replaced the traditional role of pottery with mechanized reproduction, which has in turn caused the potter to be more focused on the aesthetic than the utilitarian in industrialized nations.

Traditionally, different world regions have produced different types of clay, also called bodies, with the potter digging clay out of natural banks in his own 'back yard.' In modern times, potters will often combine different clays and minerals to produce clay bodies suited to their specific purposes. Pottery that is fired at temperatures in the 800 to 1200 °C range, which does not vitrify in the kiln but remains slightly porous is often called earthenware or terra cotta. Clay bodies formulated to be fired at higher temperatures, which is partially vitrified is called stoneware. Fine earthenware with a white tin glaze is known as faience. Porcelain is a very refined, smooth, white body that, when fired to vitrification, can have translucent qualities. Ceramic technology is used for items such as electronic parts and Space Shuttle tiles.

The development of pottery was a milestone in human history. These durable and watertight containers enabled people to boil and steam food which allowed them to exploit new sources of food such as shellfish, acorns, and leafy vegetables. Soft boiled foods could be eaten by toothless children and the elderly, which permitted caregivers to spend more time producing food. In Japan, for instance, the introduction of pottery was followed by a population explosion.

Since pottery is a durable, man-made artifact which was utilized by various cultures around the world, it has proven to be a boon for archaeologists. Broken pottery in archaeological sites, called sherds or shards, help identify the resident culture and date the stratum by the formation, style and decoration. The relative chronologies based on pottery are essential for dating the remains of non-literate cultures and help in the dating of some historic cultures as well. Trace element analysis, mostly by neutron activation, allows the sources of clay to be accurately identified.

While ceramics had been developed much earlier in Europe, some archaeologists believe that pottery was first developed by the Jomon in Japan around 10,500 BC. It appears that pottery was then independently developed in North Africa during the 10th millennium b.p. and in South America during the 7th millennium b.p.

The invention of the potter's wheel in Mesopotamia sometime between 6,000 and 2,400 BC revolutionized pottery production. Specialized potters were then able to meet the burgeoning needs of the world's first cities.

While artistic value of Classical Greek and Roman pottery largely consisted of the surface decoration, the pottery itself was an important art form in China, where efficient kilns allowed high temperature ware to be fired with wood, long before the use of coal.

A Pottery is a facility of any size, from a modest studio to an industrialized factory, where pottery is made. Where resources are available - raw materials, workers, transportation - groups of potteries may exist. Due to the large number of pottery factories, or colloquially 'Pot Banks', the City of Stoke-on-Trent in England became known as The Potteries; one of the first industrial cities of the modern era where as early as 1785 200 pottery manufacturers employed 20,000 workers. The Potters is the nickname of the local football club, Stoke City F.C.. The same name is used for sports teams in the one-time "Pottery Capital of the World," East Liverpool, Ohio.

Pottery production is a process where wet clay body, clay mixed with other minerals, is shaped and allowed to dry. The shaped clay body, or piece, ware or article, may be "bisque or biscuit fired" in a kiln to induce permanent changes that result in increased mechanical strength, and then fired a second time after adding a glaze or a piece may be once fired by applying appropriate glaze to the dry unfired clay and firing in one cycle.

Types of pottery

Aesthetic and artistic considerations have often been part of the formation of the pottery vessels, however modern mass production techniques have replaced the traditional role of pottery with mechanized reproduction, which has in turn caused the potter to be more focused on the aesthetic than the utilitarian in industrialized nations.

Traditionally, different world regions have produced different types of clay, also called bodies, with the potter digging clay out of natural banks in his own 'back yard.' In modern times, potters will often combine different clays and minerals to produce clay bodies suited to their specific purposes. Pottery that is fired at temperatures in the 800 to 1200 °C range, which does not vitrify in the kiln but remains slightly porous is often called earthenware or terra cotta. Clay bodies formulated to be fired at higher temperatures, which is partially vitrified is called stoneware. Fine earthenware with a white tin glaze is known as faience. Porcelain is a very refined, smooth, white body that, when fired to vitrification, can have translucent qualities. Ceramic technology is used for items such as electronic parts and Space Shuttle tiles.

The development of pottery was a milestone in human history. These durable and watertight containers enabled people to boil and steam food which allowed them to exploit new sources of food such as shellfish, acorns, and leafy vegetables. Soft boiled foods could be eaten by toothless children and the elderly, which permitted caregivers to spend more time producing food. In Japan, for instance, the introduction of pottery was followed by a population explosion.

Since pottery is a durable, man-made artifact which was utilized by various cultures around the world, it has proven to be a boon for archaeologists. Broken pottery in archaeological sites, called sherds or shards, help identify the resident culture and date the stratum by the formation, style and decoration. The relative chronologies based on pottery are essential for dating the remains of non-literate cultures and help in the dating of some historic cultures as well. Trace element analysis, mostly by neutron activation, allows the sources of clay to be accurately identified.

While ceramics had been developed much earlier in Europe, some archaeologists believe that pottery was first developed by the Jomon in Japan around 10,500 BC. It appears that pottery was then independently developed in North Africa during the 10th millennium b.p. and in South America during the 7th millennium b.p.

The invention of the potter's wheel in Mesopotamia sometime between 6,000 and 2,400 BC revolutionized pottery production. Specialized potters were then able to meet the burgeoning needs of the world's first cities.

While artistic value of Classical Greek and Roman pottery largely consisted of the surface decoration, the pottery itself was an important art form in China, where efficient kilns allowed high temperature ware to be fired with wood, long before the use of coal.

Ancient Greek Pottery

The pottery of ancient Greece is one of the most tangible and iconic elements of ancient Greek art. The colorful vases and pots of the ancient Greeks have survived in large numbers and are today highly prized as collectors items.

Ancient Greeks made pottery for everyday use, not for display, the trophies won at games such as the Panathenaic amphorae (used for storage), are the exception. Most surviving pottery consists of drinking vessels such as amphorae, kraters (bowls for mixing wine and water), hydria (water jars), libation bowls, jugs and cups. Painted funeral urns have also been found. Miniatures were also produced in large numbers, mainly for use as offerings at temples. In the Hellenistic period a wider range of pottery was produced, but most of it is of little artistic importance.

In earlier periods event quite small Greek city-states produced pottery for their own locale. These varied widely in style and standards. Distinctive pottery that ranks as art was produced on some of the Aegean islands, in Crete, and in the wealthy Greek colonies of southern Italy and Sicily. By the later Archaic and early Classical period, however, the two great commercial powers, Corinth and Athens, came to dominate. Their pottery was exported all over the Greek world, driving out the local varieties. Pots from Corinth and Athens are found as far a field as Spain and Ukraine, and are so common in Italy that they were first collected in the 18th century as "Etruscan vases". Many of these pots are mass produced products of low quality. In fact, by the 5th century BC, pottery had become an industry and pottery painting ceased to be an important art form of ancient Greece.

The history of ancient Greek pottery is divided stylistically into periods: The Protogeometric from about 1050 BC. The Geometric from about 900 BC. The Archaic from about 750 BC. The Black figure from the early 7th century BC. The Red figure from about 530 BC.

The range of colors which could be used on pots was restricted by the technology of firing: black, white, red and yellow were the most common. In the three earlier periods, the pots were left their natural light color, and were decorated with slip that turned black in the kiln.

The fully mature black-figure technique, with added red and white details and incising for outlines and details, originated in Corinth during the early 7th century BC and was introduced into Attica about a generation later; it flourished until the end of the 6th century BC. The red-figure technique, invented in about 530 BC, reversed this tradition, with the pots being painted black and the figures painted in red. Red-figure vases slowly replaced the black-figure style. Sometimes larger vessels were engraved as well as painted.

Thursday, October 11, 2007

The Black Pottery of San Bartolo Coyotepec

Located only 8 miles from Oaxaca City, the small town of San Bartolo Coyotepec is famous for its unique black pottery. Lovers of local arts and crafts will find the work quite charismatic. Each piece carries a decorative, textured, often floral motif that is finished to a highly burnished black patina. Nowadays, virtually the entire town is involved in the production and sale of this pottery. The best pieces are often the ones that derive from traditional usages that have only recently succumbed to the forces of modernity.

Until about 50 years ago, the vessels were used to transport mescal from hillside farms down to the local communities where it was sold in the markets. These three gallon pots were lashed together and carried into the towns on the backs of burros. But sometime in the 1950's, plastic jugs were introduced into the area and the much heavier clay containers were soon abandoned. Facing the demise of their livelihood, potters were forced to find new applications for their products.

A potter named Dona Rosa stumbled upon a method for making decorative black pottery from local clay. Her "secret" process was eventually uncovered and emulated by many villagers as the popularity of this new style of pottery grew. The locally dug clay is actually red, and it is the surface that blackens after it is fired in home built brick ovens. Though the potters are reluctant to reveal the actual technique, it is rumored that diesel is somehow part of the process. These murky production techniques discourage using the vessels for cooking or food storage, but it is the artistic rather than the utilitarian merits of the pottery that attract the prospective buyer.

The better showrooms display a wide range of pieces that are buffed to a warm satin luster. Each vessel seems to glow from within. The variety of textures and designs fall into several recognizable patterns, but the best pieces, usually those decorated with floral and plant motifs, always seem spontaneous rather than formulaic. One never tires of rotating a pot as the eye traces the design that never seems to repeat itself. Many a tourist has left San Bartolo Coyotepec weighted down with several pieces of this unique black pottery, wondering a little belatedly if the clothes in his suitcase will adequately cushion his precious cargo.

Source:

Type Of Pottery

There are many types of pottery available, but how do we know that which type is suitable to be used for specific purpose. By knowing their characteristics and nature will help you to decide which type that you will use effectively.

Ceramics

Generally, ceramics is the pottery ware which are coated on the surface. The example of ceramic ware that we familiar with are plates, bowl use on the dining table, sanitary ware, roofing/wall tiles, mosaic, pitchers, vase etc. The raw materials that use for making ceramics are some type of soil, rocks, stones etc. The ceramics production process, start from preparing raw material, then mixing all of component, then build up the design. There are several types of build up process, which are build up by hand, build up by using spinning round board, build up by Jigger machine, build up by using mold or build up by squeezing machine. The next step after build up the pottery shapes is drying and biscuitfiring, then coating or glostfiring. The last process of making ceramics is decoration and painting. Decoration and painting includes, drawing directly onto the surface or use sticker paper. This process, however, can be done before or after coating process.

Earthenware

The common characteristics of earthenware is it has brown or red colour, because the raw material that used to produce earthenware has mixture of iron substance. This type of raw materials is generally used for sculpture and images due to its attribute that not easily retract and riddled, so this materials will not easily crack or broken. The earthenware soil that has white colour in nature is rare, so we normally add extra substance to whiten the soil, and also increase the iron substance, which has red or brown colour. Generally the substance has the heat resistance at 1,050 degree Celsius. The charming of earthenware is its colour. Some potters don’t like to make pottery arts on the pottery ware that has white colour such as Porcelain, as a result, they tend to use earthenware to make pottery ware instead. Apart from its advantage about having attractive colour, using earthenware also save their time and cost to biscuitfiring as well. Earthenware also known as the common type of ceramics, however, the formulations and component of earthenware is vary, depending on region that they come from.

Porcelain

Porcelain is a kind of ceramics that requires heat in highest temperature among other kind of ceramics to produce. Generally, porcelain requires temperatures between about 1200 and 1400 degrees Celsius. We can differentiate porcelain from other pottery by toughness, strength and smoothness of the surface as well as consistency of colour of the pottery’s texture. Some type of pottery that made from porcelain looks very much alike glass, this type of porcelain pottery use heat from cone 8 to cone 12. According to its characteristics described above, porcelain is one of the pottery ware that popular for produce commercial products. The common product of porcelain that we are familiar with are kitchen ware (due to its high resistance to heat and electricity), medical equipments such as false teeth, caps etc.

Ceramics

Generally, ceramics is the pottery ware which are coated on the surface. The example of ceramic ware that we familiar with are plates, bowl use on the dining table, sanitary ware, roofing/wall tiles, mosaic, pitchers, vase etc. The raw materials that use for making ceramics are some type of soil, rocks, stones etc. The ceramics production process, start from preparing raw material, then mixing all of component, then build up the design. There are several types of build up process, which are build up by hand, build up by using spinning round board, build up by Jigger machine, build up by using mold or build up by squeezing machine. The next step after build up the pottery shapes is drying and biscuitfiring, then coating or glostfiring. The last process of making ceramics is decoration and painting. Decoration and painting includes, drawing directly onto the surface or use sticker paper. This process, however, can be done before or after coating process.

Earthenware

The common characteristics of earthenware is it has brown or red colour, because the raw material that used to produce earthenware has mixture of iron substance. This type of raw materials is generally used for sculpture and images due to its attribute that not easily retract and riddled, so this materials will not easily crack or broken. The earthenware soil that has white colour in nature is rare, so we normally add extra substance to whiten the soil, and also increase the iron substance, which has red or brown colour. Generally the substance has the heat resistance at 1,050 degree Celsius. The charming of earthenware is its colour. Some potters don’t like to make pottery arts on the pottery ware that has white colour such as Porcelain, as a result, they tend to use earthenware to make pottery ware instead. Apart from its advantage about having attractive colour, using earthenware also save their time and cost to biscuitfiring as well. Earthenware also known as the common type of ceramics, however, the formulations and component of earthenware is vary, depending on region that they come from.

Porcelain

Porcelain is a kind of ceramics that requires heat in highest temperature among other kind of ceramics to produce. Generally, porcelain requires temperatures between about 1200 and 1400 degrees Celsius. We can differentiate porcelain from other pottery by toughness, strength and smoothness of the surface as well as consistency of colour of the pottery’s texture. Some type of pottery that made from porcelain looks very much alike glass, this type of porcelain pottery use heat from cone 8 to cone 12. According to its characteristics described above, porcelain is one of the pottery ware that popular for produce commercial products. The common product of porcelain that we are familiar with are kitchen ware (due to its high resistance to heat and electricity), medical equipments such as false teeth, caps etc.

Subscribe to:

Comments (Atom)